Every reclaimed board has a past—and at Manomin Resawn Timbers, that past is honored through precision, patience, and purpose. From towering timbers once held high in century-old factories to weathered planks that lined forgotten barns, each piece begins a new journey the moment it enters our shop.

At the heart of that transformation is expert wood milling, a process that turns salvage wood into functional works of art. Supported by careful wood treatment, high-temperature wood kiln drying, and the steady hands of our seasoned woodshop team, we bring history home—beautiful, balanced, and ready to be lived in once again.

Salvaging the Past: Where the Journey Begins

Long before our reclaimed wood entered the shop, it stood as the bones of America’s early industry—barns, farmhouses, warehouses, and factories born of the Industrial Revolution. These structures weren’t just built to last; they were built with what was nearby, drawing from the dense, towering old growth forests that blanketed the region.

Local species like oak, pine, and fir were chosen for their strength, availability, and natural resilience. What was once a practical building material has become a rare and storied resource, full of character and charm. Today, that same salvage wood forms the foundation of our work, its legacy carried forward through every grain we reclaim.

A Clean Slate: The De-Nailing Process

Once salvage wood arrives at our woodshop, the first task is to uncover what lies beneath the surface. Years of use often leave behind nails, bolts, and bits of metal that must be removed before the wood can be safely worked.

Our suppliers perform an initial surface check, but we take the process much further. Using expertise gained through years of experience and the same metal detector wands used in airport security, we search each board to ensure no metal remains to damage our tools or cause safety concerns down the line.

This meticulous approach protects our machinery and preserves the integrity of every plank. It also sets the stage for clean, safe, and precise wood milling down the line.

Kiln Dried to the Core: The Power of Wood Treatment

Before reclaimed wood can become part of your home, it must be stabilized to withstand the seasons. That’s where our wood kiln process comes in, carefully drying each board until it reaches its equilibrium moisture content.

This balance between the wood’s internal moisture and the surrounding environment ensures the boards stay true, minimizing shrinkage, warping, and future movement. But kiln drying does more than protect the shape of the wood, it also protects your space.

The intense heat eliminates any insects or larvae hiding deep within the grain, leaving nothing behind but clean, safe, and beautifully seasoned material. Not every reclaimed wood provider includes this step, but we believe it’s essential to delivering a product you can trust for generations.

Craft in Every Cut: The Wood Milling Process

After kiln drying, the real transformation begins. Whether we’re working with board stock or timbers, wood milling is where function meets artistry in the hands of our skilled craftspeople.

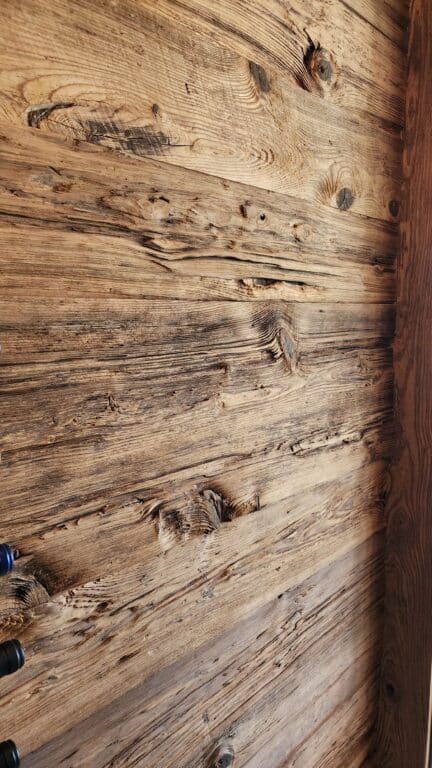

Board stock arrives in various states of wear, with each piece telling a different story. Some boards are warped or uneven, others bear the marks of decades of use, but all are full of potential waiting to be revealed.

Our team mills each board to achieve clean lines and level surfaces, preparing them for applications like flooring, wall paneling, or custom box beams. Depending on the desired finish, boards can be skip planed to highlight a blend of original face and freshly milled surface, or milled completely smooth for a modern look that still holds its historic core.

Timber stock offers even more flexibility in form and function. Some timbers are kept whole, their size and strength ideal for exposed ceiling beams or structural accents that bring warmth and authenticity to a space.

Others are milled down into planks, giving us the material for wide paneling, mantels, or additional flooring options. Every decision—from the depth of a cut to the final surface texture—is guided by both the wood’s natural character and the needs of the space it will eventually call home.

Finishing Touches: Surfacing Options and Aesthetic Styles

Once the wood is milled, the final touches help shape its identity. Surface treatments and style choices bring out the wood’s beauty while honoring its unique past.

Some of our reclaimed wood products are organized by species, each with its own tone, grain, and feel. Our antique oak, elm, and ash selections offer timeless warmth and durability, perfect for a variety of architectural and design settings.

Other selections are defined by story and origin, chosen for the character they carry. Our mixed hardwoods come from 19th-century barns, bringing a rich blend of textures and tones shaped by time and weather.

Hand hewn timbers, still bearing the marks of adzes used before the advent of circle saws, showcase craftsmanship from a slower, more deliberate era. And our weathered antique style—selected from a mix of softwoods like hemlock and pine—offers a softer palette and rustic charm drawn from turn-of-the-century structures.

Each board and beam is finished to enhance, not mask, its natural beauty. Whether smooth and refined or rough and raw, the end result is always the same: one-of-a-kind materials ready to tell their story all over again.

Trusted Craft: Installation and Legacy

By the time our reclaimed wood reaches your home, it’s been through a journey of thoughtful restoration and expert care. Each board and beam has been de-nailed, kiln dried, milled, and finished to the highest standards by a dedicated team of craftspeople.

We recommend continuing that care through the installation process by working with professionals who understand the unique qualities of kiln dried wood and the subtle variations of reclaimed material. A skilled installer brings out the full potential of our products, ensuring the wood fits seamlessly into its new home.

Whether you’re building with exposed beams, paneling an accent wall, or laying reclaimed flooring, the final step is as important as the first. We’re proud to refer homeowners to trusted contractors across Minnesota and western Wisconsin—craftspeople who share our passion for quality and respect for history.

Reclaimed with Purpose, Crafted with Care

From century-old structures to finely finished spaces, every step of our process is built on respect—for the material, the craft, and the homes our wood will soon be part of. If you’re ready to start your own reclaimed wood story, we’re here to help.

Reach out to Manomin Resawn Timbers today to explore our collections, ask questions, or connect with a trusted partner for your next project.